Disclaimer

For In Vitro Diagnostic use only

©2024, VitalScientific, Spankeren, the Netherlands

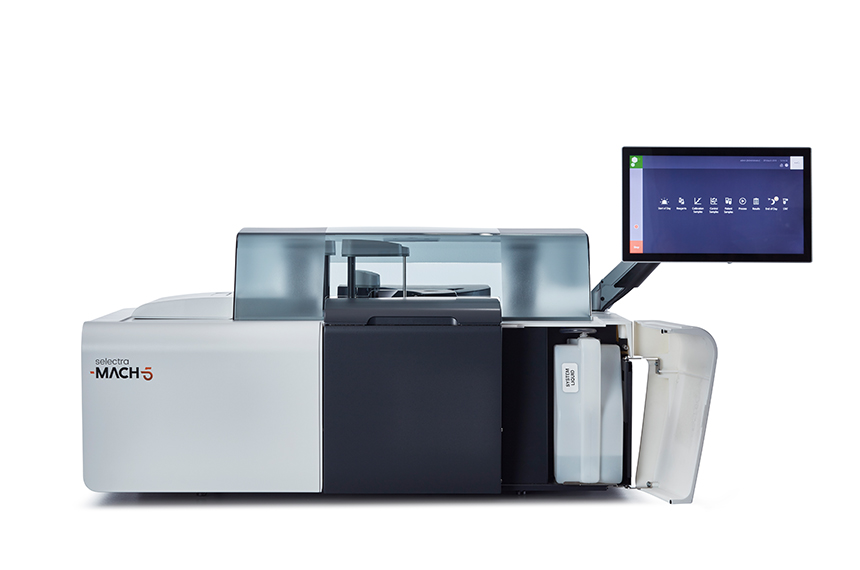

Selectra Mach5 is a registered trademark of VitalScientific.

Selectra Mach5 product specifications are subject to modification to ensure the highest quality of performance over the life of the product.

Availability may be subject to regulatory requirements. Please contact your local representative for information on the availability of this product in your area.

©2024, VitalScientific, Spankeren, the Netherlands

Selectra Mach5 is a registered trademark of VitalScientific.

Selectra Mach5 product specifications are subject to modification to ensure the highest quality of performance over the life of the product.

Availability may be subject to regulatory requirements. Please contact your local representative for information on the availability of this product in your area.